Fleetguard Nanonet Advanced Filtration Media

(11)

2025 RAM Fleetguard FK11008NN Filter Kit

- Fleetguard Atmus Filtration Technologies

$99.98

$164.33

(7)

Fleetguard LF14001NN Cummins Lube Filter

- Fleetguard Atmus Filtration Technologies

$67.85

$102.01

(7)

Fleetguard FF63041NN Nanonet Fuel Filter

- Fleetguard - Atmus Filtration Technologies

$79.98

$169.87

(3)

Fleetguard LF14002NN Nanonet Lube Filter

- Fleetguard Atmus Filtration Technologies

$72.85

$109.90

(2)

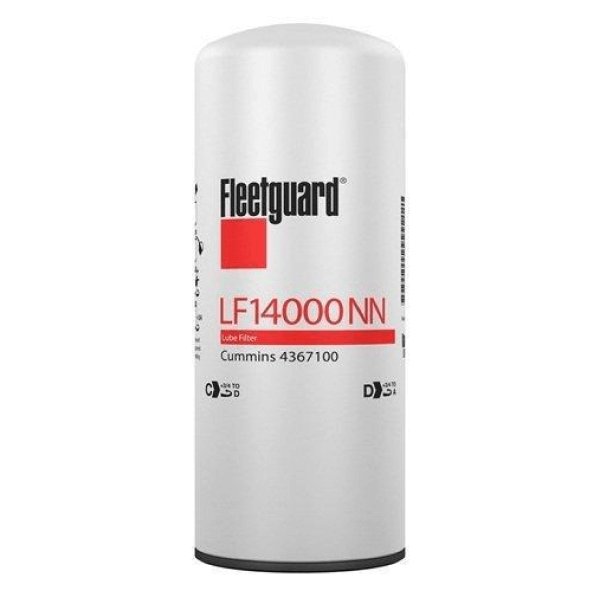

Fleetguard LF14000NN Cummins Oil Filter

- Fleetguard - Atmus Filtration Technologies

$63.98

$82.37

(5)

FASS Titanium Series Nanonet Filter Upgrade Set

- Fleetguard - Atmus Filtration Technologies

$40.98

$59.85

(5)

Cummins L9 Oil and Fuel Filter Service Kit

- Fleetguard - Atmus Filtration Technologies

$262.85

$345.98

Fleetguard FF42128NN NanoNet Diesel Fuel Filter

- Fleetguard Atmus Filtration Technologies

$45.85

$62.36

Showing

1

of

2