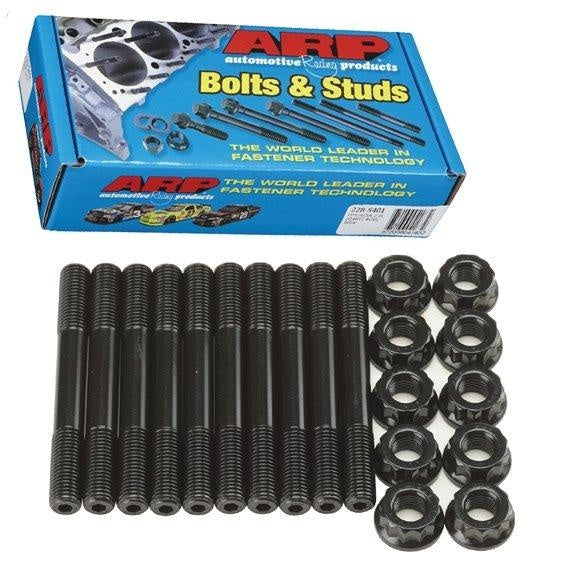

ARP Main Stud Kit

(1)

ARP 247-5403 Dodge Cummins Diesel Main Stud Kit

- ARP - Automotive Racing Products

$284.48

$375.29

(2)

ARP 230-5402 Chevy Duramax Diesel Main Stud Kit

- ARP - Automotive Racing Products

$272.85

$326.60

(2)

ARP 247-5401 Dodge 5.9L Cummins Diesel Main Stud Kit

- ARP - Automotive Racing Products

$274.05

$309.86

Showing

1

of

1