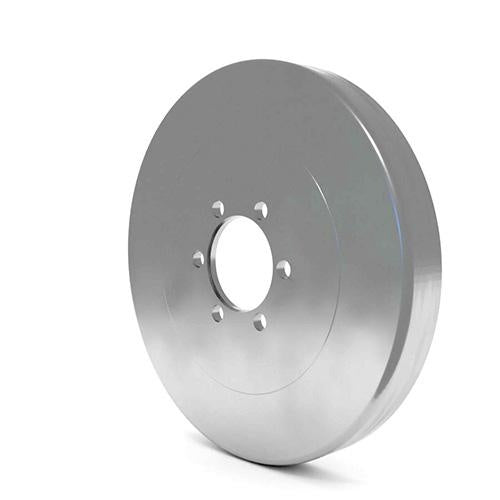

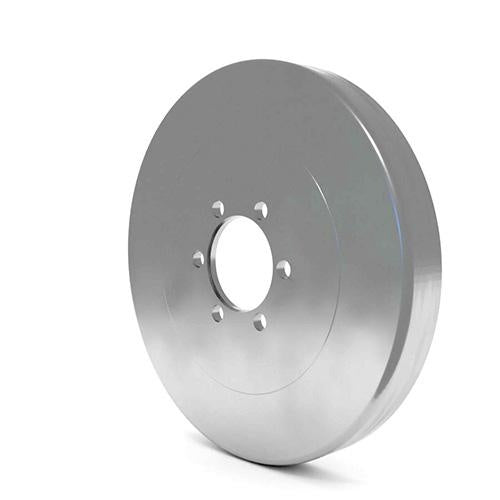

Replacement Viscous Crankshaft Damper for the Detroit Diesel Series 60 12.7L engines.

VIBRATECH 716852-000 Viscous Damper Is IN STOCK AND READY FOR IMMEDIATE SHIPMENT

This Detroit Diesel 12.7L Series 60 Crankshaft Damper is designed to provide superior quality control of torsional vibrations across all RPM levels. Bolted directly to the crankshaft, this viscous vibration damper is a precision-made, direct replacement of the OEM damper, ideal for stock motors or engines with increased power levels. The American-made damper ensures consistent protection against destructive torsional vibrations.

This Vibratech 716852-000 Harmonic Damper is for the Detroit Diesel Series 60 engine with the following displacements and variants:

- Detroit Diesel 60 Series 12.7L engines with the DDEC I Detroit Diesel Electronic Control system.

- Detroit Diesel 60 Series 12.7L engines with the DDEC II Detroit Diesel Electronic Control system.

- Detroit Diesel 60 Series 12.7L engines with the DDEC III Detroit Diesel Electronic Control system.

- Detroit Diesel 60 Series 12.7L engines with the DDEC IV Detroit Diesel Electronic Control system.

The Detroit Diesel Series 60 is an inline-six-cylinder four-stroke diesel engine produced from 1987 to 2007 in four engine variants.

This Viscous Vibration Damper is bolted directly to your Series 60 Crankshaft to control the destructive torsional vibrations. This balancer is designed to replace the OEM Detroit Diesel Damper. This viscous crank damper is designed to control torsional vibrations on stock motors or engines with increased power levels of your Series 60 Detroit Diesel. The Vibratech 716852-000 harmonic damper will provide the correct level of control of all torsional vibrations at all engine RPM levels. This American Made crankshaft damper is a precision-made superior quality torsional vibration damper.

The Detroit 60 Series diesel engine was built to last with a single overhead camshaft to operate its intake valves, exhaust valves, and fuel injector plungers. This engine's simplicity has led to many 12.7L Detroit diesel engines still being on the road today. Keep your Detroit 60 Series in use with the Vibratech Crankshaft Damper.

The Detroit Diesel 12.7L Series 60 Viscous Crankshaft Damper offers:

- Reduces Driver Fatigue

- It provides smoother engine operation at all RPMs and Power Levels

- Increase horsepower & torque

- It provides better fuel efficiency

- Extends the life of the engine

- Improves both the valve timing and the valvetrain operation.

- Paintable steel finish

- It provides optimum engine protection from torsional vibrations across the entire RPM range.

- A Vibratech TVD viscous damper reduces the risk of crankshaft failure.

- Only a precision-machined viscous damper can increase engine component life.

- Precision CNC machined, and computer-balanced components make this the best viscous damper available for your 112.7L Detroit Diesel.

This High Performance Torsional Vibration Damper for the DETROIT 12.7L SERIES 60 cross-references to:

- Detroit 23525990

- Detroit 23522891

- Detroit 9258502

Vibratech Torsional Vibration manufactures a Heavy Duty Replacement Diesel Damper that is designed and built to be a superior aftermarket vibration damper for the Detroit 12.7L Series 60 Turbo Diesel engines. The Vibratech Heavy Duty Diesel Damper design contains a free rotation inertia ring surrounded by a viscous silicone fluid that is enclosed in a laser-welded, sealed housing. This Vibratech 7176852-000 Torsional Vibration Damper is a viscous damper manufactured in a registered state-of-the-art facility that is ISO 9001-2008 certified. Vibratech Heavy Duty Aftermarket dampers are designed by engineers who understand the critical principles of physics that are used to develop harmonic dampers that control torsional vibrations. The fluid-filled Vibratech TVD® viscous harmonic dampers are the preferred heavy duty diesel engine vibration damper based on Quality, Dependability, and Longevity. Your DETROIT DIESEL® or 12.7L SERIES 60 diesel engine requires the best torsional vibration damper available, so purchase a Vibratech 7117406-000 damper.

Detroit Diesel 12.7 Liter Series 60 diesel engine dampers require replacement between 350,00 and 500,000 to ensure engine performance and reliability. When your Series 60 diesel engine is having an in-frame overhaul completed, the crankshaft damper is often overlooked. The failure to replace the crankshaft damper is an extremely expensive error.

Failing to replace a worn-out viscous crankshaft damper will not protect your engine from costly engine damage and downtime.

KLM Performance recommends regular inspection of the crankshaft damper to ensure the protection of torsional vibration, which will lead to costly engine damage and downtime.

That’s why regular viscous damper replacement in heavy-duty applications is critical to longer engine life.

The use of an overseas-manufactured Detroit Diesel damper is penny-wise and pound-foolish!

Installation of the Detroit Diesel 12.7L Series 60 Crankshaft Damper is as follows:

Install the flywheel lock (J–36375–A) to the inspection plug hole in the bottom of the flywheel housing. See Figure "Flywheel Lock"

NOTE: It may be necessary to bar the engine over using the barring tool (J–36237) so that the tool center screw is exactly between two teeth. Thread the center screw of the tool until the tip of the tool rests between two teeth of the flywheel ring gear. Tighten the knurled knob finger-tight. Install two guide studs (J–36235) to two of the holes in the crankshaft pulley 180 degrees apart.

- A light coating of an anti-seize compound should be applied to the pilot diameter (not the face of the crankshaft) to reduce future removal difficulty.

- Install the vibration damper to the end of the crankshaft.

- The six mounting holes in the damper are equally spaced, and the damper may be installed in any position.

- The part number on the face of the damper should face out, away from the engine.

- Install the crankshaft pulley or crankshaft pulley spindle to the crankshaft.

- The crankshaft pulley or crankshaft pulley spindle may be installed in any position. Refer to "1.15.3 Installation of Crankshaft Pulley.

- Install four new special bolts, with hardened washers, through the pulley or crankshaft spindle and damper into the crankshaft.

- Finger-tighten the bolts.

- Remove the two guide studs.

- Install the remaining two new special bolts with hardened washers installed.

- Torque the six crankshaft pulley bolts to 210 N·m or 155 lb·ft.

- Proceed in a clockwise direction until all the mounting bolts are torqued.

- Install crankshaft pulley and hub assembly if equipped with this pulley style. Refer to "1.15.3 Installation of Crankshaft Pulley"

- Remove the flywheel lock tool.

- Install the pipe plug to the inspection hole in the flywheel housing.

- Install the drive belts to the crankshaft pulley. Adjust the belt tensions to the specifications. Refer to "14.6.9 Drive Belts".

- Install any other components that were removed for this operation.

- Refer to "12.7 Engine Run-in Instructions" for verification of proper crankshaft vibration damper installation.

NOTICE: Crankshaft pulley and spindle mounting bolts are to be considered single-use items and must not be reused. Always use new bolts when mounting the crankshaft pulley or spindle. Reusing bolts may result in excessive bolt stretch during installation, leading to loss of bolt torque and loosening during engine operation, which may cause severe engine damage.

Detroit Diesel Series 60 Crankshaft Vibration Damper is MADE IN THE USA!